| Condition:New | Warranty:1 Year |

| After-sales Service Provided:Field installation, commissioning and training, Engineers available to service machinery overseas | Place of Origin:Shandong, China |

| Voltage:380V/50HZ or custom | Application:Dog |

| Weight:3000kg | Certification:SGS CE |

| Dimension(L*W*H):12000x1300x2500 | Power(W):45kw |

| Applicable Industries:good taste automatic dog biscuits making machine | Product name:high quality good taste automatic dog biscuits making machine |

| Capacity:60-100kg/h | Raw material:Corn Powder |

| Motor:Simens | Material:Stainless Steel Food Grade |

| Product:chewing pet food | Energy:Electricity or Gas |

| Type:Single Screw machine | Automatization:Fully automatic |

Description:

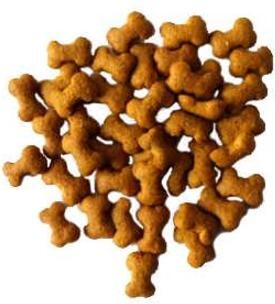

Pet chews take starch as raw materials with scientific configuration and are extruded from dog biscuits making machine, it can be made into different kinds of shapes such as stick, bone, bi-color, bi-flavor etc. This kind of food not only provide protein, fat, vitamin for dogs, but also satisfy the dog's nature hobby. It has following features: strong teeth, cleaning mouth and teeth. The product can be in many shapes, like twist, core-filling and so on.

Features:

Can process plant or animal material intended for consumption by dogs or other canines

In extruder, ingredients are cooked under intense heat and pressure as moving toward the open end of extruder where ingredients pass through shaping die and knife

Raw materials adopt corn flour and fish meal

Various shapes are available

Flow chart: mixing system, extrusion system, drying system, flavoring system and packing system

Nice design and high automation

With building blocks system structure and self-cleaning functions

Our services:

We Provide Satisfied Service & Turnkey Solution:

Before sale services:

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales:

1.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2.Welcome to visit our factory or the domestic clients' factory.

3.Inspect the machine before leaving the factory.

After sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. We will provide 1-2 engineer to the client's factory for the installation and teach totally in 10 days. The client need provide room, food, round-trip transportation, visa fee and a nominal $40 daily subsidy per person.

Copyright © 2017 - 2025Shandong Yuansu Mechanical Equipment Manufacturing Co., Ltd. All Rights Reserved